flange

Types of Pipe Flanges

- Socket-Weld Flanges

- Slip-On Flanges

- Lap Joint Flanges

- Weld Neck Flanges

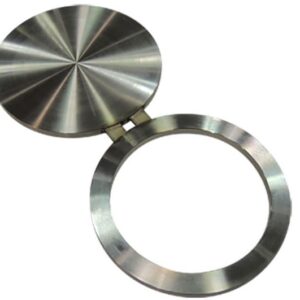

- Blind Flanges

- Reducing Flange

- Expander Flange

- Flangeolet / Weldoflange / Nippoflange

The pipe flanges are the second most used joining method after welding. They are used when joints need dismantling. It provides flexibility for maintenance. Flange Connects the pipe with various equipment and valves. Breakup flanges are added to the pipeline system if regular maintenance is required during plant operation.

A flanged joint comprises three components; flanges, gaskets, and bolting and assembled by pipefitter. Special controls are required to select and apply all these elements to attain a joint, which has acceptable leak tightness.

However, it is not advisable to use a flange connection in underground piping when it is supposed to be buried. The flange is also the most common source of leak and fire in a process plant. There are a variety of flanges available to suit the requirements. A flange can be classified in several alternate ways based on the following:

- Types of Connection

- Flange facing Types

- Pressure-Temperature Ratings

- Material Types

Showing all 7 results